-

Englisch

Englisch

Industries

Full competence ahead.

MEERANER Dampfkesselbau serves several industrial core sectors at the same time with energy technology and power plant construction on the one hand and demanding process plant engineering on the other hand. Our customers can access a comprehensive product and service portfolio all over the world: with convincing quality and the whole experience of MEERANER Dampfkesselbau.

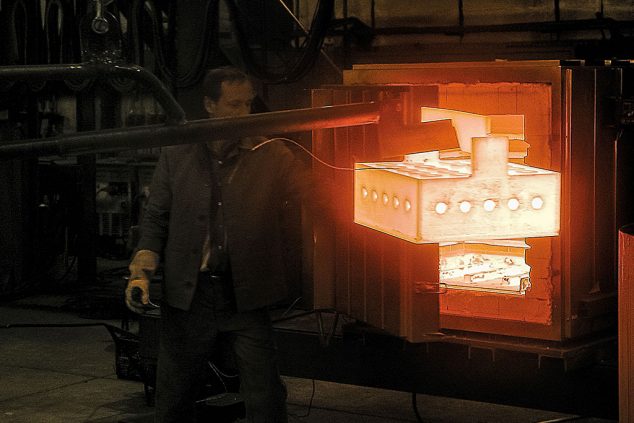

Energy technology and power plant construction

Continuous operation or reserve: Each power plant must work reliably and without malfunctions. We produce high-quality components, such as membrane walls, superheaters, headers and burners. Always robust, durable – and economic. Permanently.

Fossil fuels: Components for a secured electricity and process steam generation with gas, oil, lignite or hard coal. Each product from MEERANER Dampfkesselbau is extremely stable and reliable.

Waste incineration: A hot issue requiring heat-resistant, robust and durable boiler components. The demanding components are produced by us. For small municipal plants. Or for large industrial systems.

Biomass: Modern plants need contemporary, specially produced boiler components of different sizes. This is precisely what we produce – of MEERANER quality.

Process plant engineering

Piping systems, heat exchangers, special fittings or the complete installation on one skid: MEERANER Dampfkesselbau offers the right solutions. And special process equipment for the chemical, paper and steel industry as well as for the oil and gas industry. From the traditional heat exchanger to containers and up to special fittings. We specifically produce these according to your requirements.

Chemical industry: Fertiliser industry, petrochemistry, plastics industry: Each sector has particular requirements. We understand what you need – and provide the suitable solutions with vessels, piping systems, heat exchangers and much more.

Steel industry: steel production without reliable cooling process. We provide what is needed: extremely robust components such as cooling chimneys, waste heat systems or lance domes.

Paper and timber industry: Special branches of industry need special solutions. MEERANER Dampfkesselbau delivers, for example, drying drums and process steam generators.

Oil and gas industry: No matter if transport or processing in refineries, cracking plants or within other procedural processes: The special fittings, heat exchangers and vessels from MEERANER Dampfkesselbau meet your high requirements.

- Industries & products

Products

Successful worldwide.

Comprehensive, demanding and in operation all over the world: We provide complex pressure parts and components for the areas of energy technology and power plant construction as well as process plant engineering. Here, you will find an overview of our delivery programme.

Membrane walls,

cooling screens, bulkheads

Traditional tube-web-tube connections in boiler engineering for waste incineration plants as well as for industrial power plants. Also available as a modified version with wear and corrosion resistant composite pipes (read more). In order to ensure a consistently high quality, we produce the components on large gantry and continuous welding machines.

Vessels, headers,

distributors, coolers, separators

They are the all-rounders: highly resilient pressure parts, which work in refineries, gas handling installations or in power plant boilers. We produce all necessary headers, distributors or vessels precisely according to your requirements – and of typical MEERANER quality.

Burners for pulverised coal-,

oil-, gas- and biomass-fired boilers

Electricity generation or process steam/electricity generation: There are burners from MEERANER Dampfkesselbau in almost all areas of energy transformation. We produce the perfect burner, which is adapted precisely to your application conditions, with much know-how.

Special fittings

If things become more complicated, this is the time for MEERANER Dampfkesselbau: We produce non-standard blanks for special fittings made of highly heat resisting steels. Depending on pressures, temperatures and chemical resistances, we weld individual components to highly resilient components, such as ball valves, shut-off valves, distributors, reducers, etc.

Black-white connectors

Modern boiler engineering: impossible without nickel base materials and chromium-nickel steels. Therefore, we specialise in fine-grained structural steel welded joints and high-alloy materials. With the black-white-connectors from MEERANER Dampfkesselbau, you can easily change from steel to stainless steel materials within a pipeline. A huge relief on construction sites under assembly conditions: fully automatic, 100% tested, economic.