- Services & Support

-

Englisch

Englisch

Service

Consistently competent.

First-class service. A team, which does not only know its job, but also masters it even if it gets complicated. In addition to this, a keen sense for efficient solutions from which you can benefit in the long run. You can rely on MEERANER Dampfkesselbau.

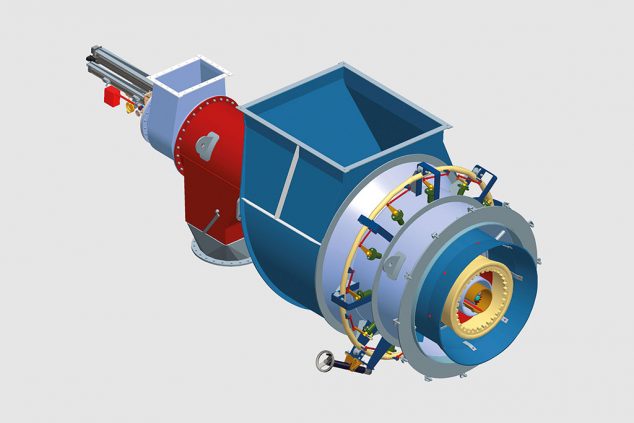

Spare parts service

With us, your plant will maintain a stable operation in the long run. As an experienced manufacturer, we produce and deliver original spare parts of MEERANER quality for you. On time, reliable – and durable, even for other brands. In order to ensure that you have the correct part at the place where you need it, we also take care of logistics.

- 1:1 spare part replacement

- Component optimisation and adaptation (engineering)

- Component assessment and repair

- Advice for conservation, storage and procurement times

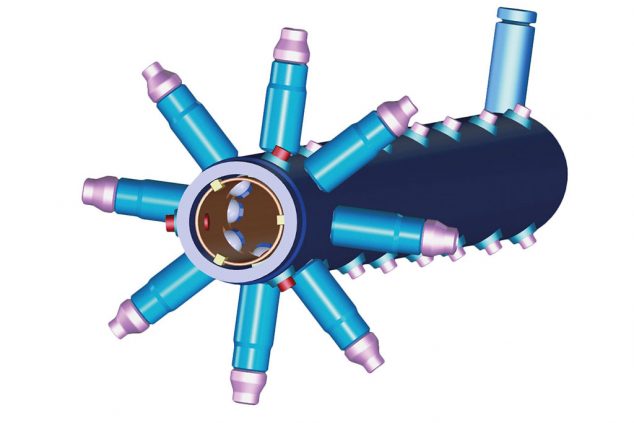

Wear protection

How trouble-free and efficient a plant works always depends on the condition of its components. Particularly in case of waste incineration plants, wear is a decisive issue. MEERANER Dampfkesselbau has appropriate counterstrategies.

Cladding

Boiler components are particularly stressed in incineration plants: Corrosive and erosive material abrasion causes many components to wear particularly quickly. We counteract this with semi-finished products – equipped with a welded, very robust protective layer made of alloy (nickel base materials).

The result are particularly robust and durable tubes/tube bundles, membrane walls or also headers. MEERANER Dampfkesselbau also turns highly stressed burner components into durable, wear-resistant components: by means of hard cladding with wolfram carbide and/or nickel welding fillers. This efficient wear protection is also possible in retrospect as retrofitting.

Assembly works and supervision of the construction site

We will realise your complex reconstruction and modernisation measures together with our experienced installation partners. Include MEERANER expertise in your project: We are at your disposal on every construction site – during the entire installation time: with inspections, interfaces determined together and comprehensive planning. For example, we develop optimised production processes for each component to be replaced. And we coordinate personnel and equipment in good time. In this way, your downtimes are minimised as much as possible – even in extraordinary situations.

- Services & Support

Engineering

Corresponds exactly.

Engineering for new and existing plants, from the basics to the detail and with future reliability: Energy technology and power plant construction as well as process plant engineering at the highest level. We plan, calculate and take care of the entire design – with decades of experience, the most modern technology and experienced partners.

Basic and detailed engineering

Everything is – and remains – in motion, optimisations of old plants, changed operating parameters or re-constructions of components: MEERANER Dampfkesselbau will always bring you safely to the future.

With modern CAD software like Inventor or Creo, we also integrate your plans without difficulties. We also perform the production upon request – of uncompromised MEERANER quality.

- 3D models and drawings

- Adjustments to changed application conditions

- Use of new technologies/replacement of components

- Modification to other fuels

- Retrofitting and expansion

- Rehabilitation and modernisation

- Technical consulting and feasibility studies

Calculation and design

Which parameters are available? What has to be dimensioned in which way? How can future requirements already be considered beforehand? What can be optimised at which point with which effort? Our experts know what really matters. In every detail.

- Design/calculation/evaluation of process data

- Mathematical preliminary test by the TÜV (components and parts)

- Collection and evaluation of operating data

- Damage survey/error analysis/process optimisation

- Performance and energy optimisation

- Efficiency-boosting measures

- Adjustments to changed application conditions/official requirements/tighter limits

- Services & Support

Welding Technology

More skills.

As an entity in the area of welding technology, which has been respected internationally for decades, know-how is a key factor for us. Equally important: permanent exchange and new impulses. We cooperate with companies, institutes and universities. And we occupy a leading position regarding the use and processing of new, demanding materials and welding filler materials. Much knowledge which does not only contribute to our products, but also to our advisory service and the MEERANER academy with its challenging training programmes.

Welding advice

Know-how at first hand. By experts for experts. And above all, with direct practical relevance. We advise you on everything concerned with welding techniques. In this way, you can make progress without detours.

- Handling of relevant guidelines

- Material selection, processing and possible applications

- Quality standards and valid guidelines

- Development of test plans and test instructions regarding the non-destructive test

- Development of welding repair technologies

- Preparation of welding procedure and production control test documents

- Development of welding and heat treatment instructions

- Preparation of work samples / tests and test implementations

- Organisation and implementation of welding procedure tests

Materials

From proven-traditional to highly innovative: We work with a large variety of materials – and we know what is possible. For example:

- Traditional high-temperature steels/tubes from P235GH (1.0435), P265GH (1.0425) to 16Mo3 (1.5415), 13CrMo4-5 (1.7335) and up to 10 CrMo9-10 (1.7880)

- High-temperature steels, primarily consisting of bainite structures such as 15NiCuMoNb5-6-4 (WB36) (1.6368)

- Martensitic chromium steels such as X20CrMoV11-1 (X20) (1.4922), X10CrMoVNb9-1 (P91) (1.4903), X11CrMoWV9-1-1 (E911), X10CrWMoVNb9-2 (P92) (1.4901), X12CrCoWMoVNb12-2-2 (VM12-SHC) (1.4915)

- Highly heat resisting steels such as 7CrMoVTiB10-10 (T24) (1.7378)

- Heat-resistant ferritic and austenitic steels such as X10CrAlSi18 (1.4742), X10CrAlSi24 (1.4762), X15CrNiSi20-12 (1.4828), X15CrNiSi25-20 (1.4841)

- Austenitic steels such as X6CrNiMoTi17-12-2 (1.4571), X6CrNiTi18-10 (1.4541), X3CrNiMoBN17-13-3 (1.4910), DMV 347 HFG or TP 347HFG (1.4908), S304H or DMV 304H Cu (1.4907), Sanicro 25, HR3C or DMV 310 N (1.4952)

- Nickel-based alloys such as X5NiCrCeNb32-27 (AC66) (1.4877), NiCr23Fe (Alloy 601) (2.4851), NiCr22Mo9Nb (Alloy 625) 2.4856), NiCr23Co12Mo (Alloy 617) (2.4663), HR6W, Alloy 740

Welding procedures and special welding equipment

We are proficient in all common welding procedures according to DIN EN ISO 4063 such as 141 (GTAW), 111 (SMAW), 135 (GMAW), 136 (FCAW-cored filler wire), 12 (SAW) and 78 (stud arc welding). We really enjoy complicated issues: When it gets complicated, we find efficient solutions reaching far beyond the conventional.

- SAW gantry and continuous welding machines for the manufacture of seal-welded tube walls

- 12-axes GMAW robot gantry welding machine with swivelling rotary table

- SAW welding tractors

- Automatic GTAW circumferential welding machine

- GTAW/SAW header stub welding machine (automated)

- Automatic SAW circumferential and longitudinal welding machine

- Services & Support

Contract manufacturing

Let the MEERANERS perform the work.

You have the great tasks, we have the appropriate capacities and skills: We will support you with traditional contract services according to your needs. Please contact us. And stay flexible in this way, just like you want to be.

Special welded constructions

Welded construction made of high-temperature steel. From a partner, who really masters the machining of this demanding material. MEERANER Dampfkesselbau implements your ideas quickly, purposefully and with constructions which deliver what they promise. Let us talk about your project now – no matter how big and extraordinary.

- Realisation of demanding special welded constructions

- Production of steel and sheet constructions according to customer specifications

- Heat treatment and straightening works

- Welding consulting

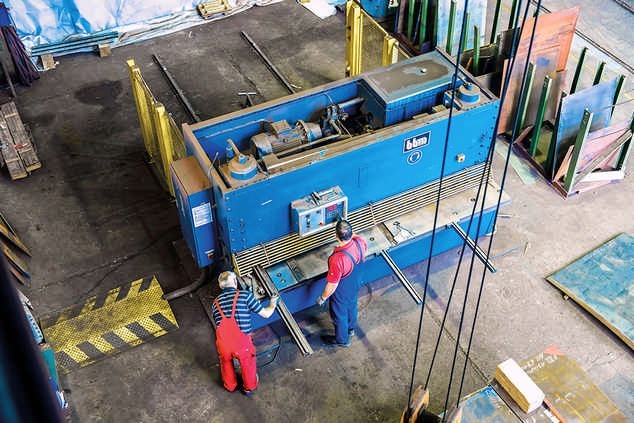

Material blanks

Perform even better: Let us perform your cutting tasks. Clean, on time and for a fair price.

3D plasma cutting machine

Dimensions

L=6,000 mm x W=2,500 mm x max. material thickness=40 mm

Programming (eg for contour shapes) possible according to customer specifications

Band saw (semi-automatic)

Dimensions

max. Ø 1,020 mm

Band saw (fully automatic)

Dimensions

max. Ø 300 mm

Plate shear

Dimensions

W=3,000 mm x material thickness= max.16 mm

Bending, rolling & chamfering

Tubes, steel sheets or flat steel? We bring your material into the desired form – from a small tube to the membrane wall segment with a length of up to 33 metres:

Membrane wall bending (segments)

Membrane wall bending (segments)

L=33,000 mm x W=2,500 mm x bending angle max. 125°

Web width

up to 100 mm

Tube diameter

25 mm to 101.6 mm

CNC tube bending (mandrel-less booster bender)

Radii

depending on wall thickness and tube diameter

Tube diameter

21 mm to 101.6 mm

4 rollers CNC round bending (rolling) of steel sheets/flat steels

4 rollers CNC round bending (rolling) of steel sheets/flat steels

W=3,000 mm x material thickness= max. 32 mm

Cylindrical and conical rolling

3 rollers profile bending of tubes and flat steel

Dimensions radii

min. radius: 300 mm / max. radius: 3,000 mm

Dimensions

max. tube diameter=88.9 mm / max. material height

flat steel width

max. 100 mm

CNC press brake

Dimensions

W=3,100 mm / bending capacity=1,600 kN

Material thickness

max. 10 mm

CNC turning & milling

Maximum precision for efficient machining – we will also jump-start your series production with CNC. Skilfully combined with the know-how and experience of MEERANER Dampfkesselbau.

CNC turning – universal turning machine

Max. component dimensions

L=1,050 mm x Ø 465 mm

Single-item and series production possible

Servo turret for turning-milling machining (complete machining of workpieces)

CNC milling – universal vertical milling machine

Max. component dimensions

X=1,100 mm x Y=560 mm x Z=510 mm

Additional 4th axis (rotary table)

Single-item and series production possible

CNC boring & milling – table boring machine

Component dimensions

X=1,985 mm x Y=1,620 mm x Z=1,960 mm

360° rotating table

Single-item and series production possible

Manual and automatic contract welding

Manually with the whole experience and competence of MEERANER Dampfkesselbau. Or automatically with the capacity and size of modern welding machines. You have the components – we have the solution.

Manual welding procedure

GTAW (141), SMAW (111), GMAW (135), FCAW-cored filler wire (136) and stud arc welding (78)

Special welding equipment

Automatic GTAW and SAW circumferential welding machines, SAW welding tractors, SAW gantry welding machines as well as several special welding devices

12-axis robot gantry welding machine

GMAW process for V- and fillet welds

Max. component dimensions

L=7,000 mm x W=2,800 mm x H=2,800 mm / Ø 3,500 mm

Material thickness

3 mm – 40 mm

max. component weight for clamping

2,200 kg

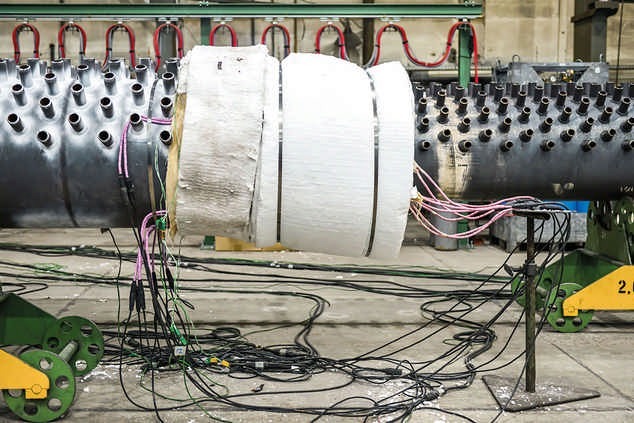

Heat treatment

Stress relief heat treatment, normalisation, low hydrogen annealing: We will perform the most diverse heat treatments for you – even the heat treatment of large parts.

Procedures & services

Stress relief heat treatment

Low hydrogen annealing

Normalisation

Annealing with resistor elements

Annealing with resistor elements

Mobile lightweight construction furnace (modular) for special dimensions

Heat treatments for the implementation of welding works (preheating and heat retention)

Large annealing furnace (dividable into compartments)

Max. temperature

800°C

Annealing chamber

L=12,800 mm x W=1,300 mm x H=1,300 mm (dividable into 3 compartments)

Up to three independently adjustable temperature zones

Circulating hot air

Small annealing furnace

Max. temperature

1,280°C

Annealing chamber

L=710 mm x W=800 mm x H=560 mm

Compressed air blasting & industrial painting

Removal of old coatings, new coating of surfaces, preservation of values: Let us perform your blasting and painting works. And you can benefit from clean, economic work.

Blasting cabinet

Work space

L=7,000 mm x W=5,000 mm x H=4,000 mm

Manual blasting with blast gun and various blasting abrasives

Continuous blasting machine

Component dimensions

L=12,000 mm x W=1,250 mm x H=500 mm

Automatic blasting with steel shot

Painting cabin

Work space

L=12,000 mm x W=6,000 mm x H=5,000 mm

Heating and humidifier system as well as cranes (2t)

Procedure

Compressed air and airless spraying with various painting and coating materials

Open space

Work space open space

L= 30,000 mm x W= 14,000 mm x H= 7,500 mm

Procedure

Compressed air and airless spraying with various painting and coating materials